Ultimate Overview to DTF Printing Strategies for Stunning Textile Styles

Getting started on the trip of mastering DTF printing techniques can open up a world of opportunities for developing visually fascinating fabric designs. As the fabric industry remains to advance, remaining ahead of the curve with innovative printing methods is essential. In this guide, we will certainly check out the elaborate details of DTF printing, from realizing the fundamental essentials to unraveling progressed shade methods that can raise your layouts to new heights. Stay tuned as we explore the nuances of selecting the right materials, developing the printing process, and getting over typical obstacles to attain magnificent outcomes.

Understanding DTF Printing Essentials

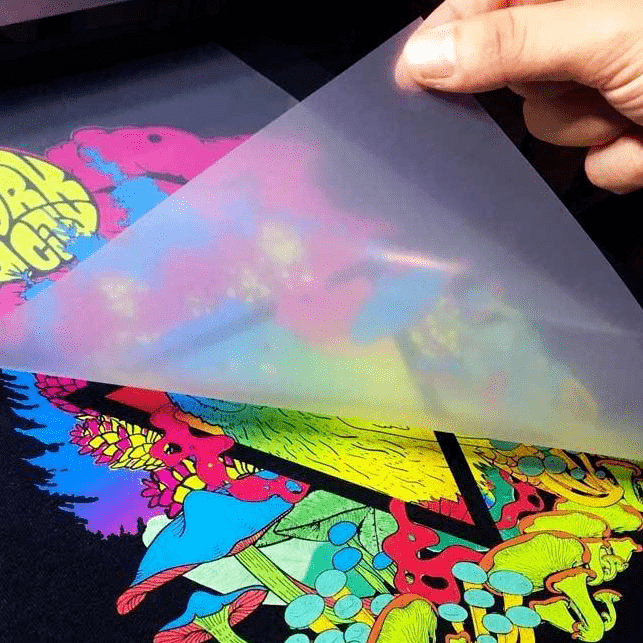

DTF printing, a process that includes transferring styles from a special movie to fabrics making use of warmth and pressure, develops the structure of fabric printing methods. This cutting-edge technique allows for premium, lively designs to be seamlessly transferred onto numerous fabrics with accuracy and detail. The primary step in DTF printing involves producing or selecting a layout that will be printed onto the fabric. This style is then published onto a special movie making use of a DTF printer, which makes use of specific dyes or pigments to ensure shade precision and toughness.

The final result is a stunning, lasting fabric style that is cleanable, versatile, and immune to fading. Generally, recognizing the essentials of DTF printing is crucial for understanding this modern-day fabric printing method.

Selecting the Right Fabric Materials

Having developed the fundamental principles of DTF printing methods for fabric layouts, the following important factor to consider exists in picking the ideal textile products to enhance this innovative process effectively. Furthermore, the stretchability of these materials can suit the warm transfer process included in DTF printing without misshaping the layout. By picking the right fabric materials, developers can optimize the potential of DTF printing to develop sensational and long-lasting textile styles.

Mastering the Printing Refine

To succeed in DTF printing methods for textile layouts, understanding the printing process is essential for achieving high-quality and consistent results. The temperature level, stress, and period of warmth application have to be thoroughly managed to ensure correct attachment of the design to the fabric. By sharpening each of these steps in the printing procedure, developers can consistently produce long lasting and magnificent textile layouts with DTF printing techniques.

Enhancing Designs With Shade Strategies

Additionally, trying out shade slopes can bring a feeling of motion and fluidness to the design. By mixing shades perfectly, a slope result can be attained, including a modern and vibrant touch to the textile layout. Additionally, using color obstructing techniques can create bold and striking visuals by comparing different strong shades in distinctive sections of the style.

In addition, including metal or neon shades can give a unique and appealing component to the textile style, making it stand apart and emanate a feeling of vibrancy. When strategically applied, these shade strategies can elevate the total aesthetic allure of textile layouts, making them much more my site exciting and unforgettable.

Troubleshooting Common DTF Printing Issues

After exploring different shade methods to enhance textile layouts, it is necessary to attend to common DTF printing problems that might arise throughout the production process. One usual concern is poor bond, which can arise from inappropriate curing temperatures or times. To resolve this trouble, make certain that the curing setups are accurate and that the glue utilized appropriates for the certain fabric being published on. Another frequent difficulty is color disparities, where colors might show up differently than expected. This can be caused by inaccurate color profiles or setups in the printing software program. To tackle this, double-check the color settings and accounts to ensure they match the desired layout. In addition, problems with photo clarity and intensity can occur because of low-resolution images or find more information incorrect printing techniques. To address this, constantly make use of top notch images and readjust the printing setups for optimal clarity. By recognizing these usual troubles and carrying out the needed troubleshooting steps, you can improve the total quality of your DTF published fabric styles.

Conclusion

To conclude, grasping DTF printing methods is necessary for developing spectacular fabric layouts. By recognizing the fundamentals of DTF printing, selecting the appropriate products, and boosting designs with color methods, one can accomplish impressive outcomes. It is necessary to troubleshoot usual issues that may emerge during the printing procedure to ensure an effective result. With method and interest to information, one can develop stunning and one-of-a-kind fabric layouts utilizing DTF printing strategies.

DTF printing, a process that entails transferring styles from an unique film to fabrics using warm and stress, forms the structure of fabric printing methods.Having actually established the foundational concepts of DTF printing methods for fabric designs, the next crucial consideration lies in choosing the appropriate textile products to match this innovative procedure efficiently. By selecting the right fabric products, developers can make the most of the possibility of DTF printing to produce resilient and magnificent fabric styles.

To stand out in DTF printing methods for fabric styles, grasping the printing process is necessary for achieving top notch and regular results. DTF Printing. By honing each of these actions in the printing procedure, designers can regularly create sensational and long lasting textile styles with DTF printing methods

Comments on “The Ultimate DTF Printing Guide: Methods, Materials, and Applications”